Noroil gewinnt den Eurol Specialty Dealer of the Y...

Noroil gewinnt den Eurol Specialty Dealer of the Year Award 2024 dank starkem Wachstum im Bereich industrieller Schmierstoffe und technischer Flüssigkeiten in Norwegen.

22. August 2019

Dirk van der Veen, Business Development Manager at Eurol Specialty Lubricants, has the most fun job in the company. He is involved in the development of high-tech lubricants and cleaners for agriculture, heavy construction, earthmoving, offshore, transport, and industry. We are invited to Dirk for an audience; he talks about the importance of specific lubricants, greases, and additives that lead to less consumption, more power, and a much longer lifespan of parts and machines.

What makes working at Eurol Specialty Lubricants so much fun? "With regular lubricants, you can't deviate from the OEM specifications prescribed by manufacturers, understandably. With Eurol Specialty products, we don't have to; we can go all out." For road vehicles, the focus is on fuel saving, and in racing, it's all about performance. Eurol helps racing teams perform better. "There, you have less to do with, for example, after-treatment and soot filters, and we can freely test new technology and products. What works best there?" Eurol Specialty Lubricants is not only active in racing but also provides high-quality products for the industry, offshore, heavy construction, earthmoving, and the transport sector. The range is based on Eurol's self-developed SYNGIS technology.

Extreme Conditions Grease is grease, right? Van Der Veen: "Not exactly, our lubricants are completely different in composition compared to regular lubricants." Everyone knows lithium or EP2 greases, which are made on price. They are not that expensive and work well under very light conditions. But our clients operate their equipment and machinery under heavy or extremely heavy conditions. "In racing, industry, or heavy construction, you deal with extreme temperatures, shock loads, dirt, water, salt, acid, you name it." This requires very specific formulations of lubricants that contribute to better performance and longer lifespan of equipment and machinery. "All our Specialty greases have different thicknesses, base oils, and additives; they're not comparable to a regular EP2 grease." The Eurol Specialty greases all have different, specific properties. "They flow differently, have a different base oil: synthetic, mineral, or a mix of both. Also, our greases contain SYNGIS Technology." It's important to know the application for the right product advice.

Ice-Cold Liquid A transporter active in Scandinavian countries wants the tail lift of his truck to be easily operable at -35 °C. "A regular EP2 grease becomes a block of concrete at such temperatures. The grease we have developed remains perfectly liquid down to -42°C." Other greases in our range are developed specifically for heavy loads at high temperatures. "We offer a very diverse package of lubricants and cleaners. From greases for very specific or heavy-duty applications to products that are broadly deployable for lubricating dishes, wheel bearings, and sliding parts."

Huge Cost Savings Using the right grease saves money. "The costs saved by using specially developed greases and lubricants can be enormous. One of our clients has a large wood shredder, a huge machine. It has pin-bush connections. Such a machine has to absorb enormous blows due to the thick logs. The grease they used only stayed for two hours; after that, it had to be lubricated again. Our grease stays for 48 hours. The customer is delighted because the machine's full capacity is thus utilized. It gives the customer more than just time savings. The shredder previously needed a revision every six months, costing €30,000. They have been using our grease for two years now, and since then, a revision has not been needed. They now use a tenth of the amount of grease they used before, saving about half a ton per year in maintenance costs. That's huge."

Strong in Transport Eurol does a lot in the transport sector. "The exhaust of many Euro 5/6 engines is curled around the leaf spring, giving off very high radiant heat. If the pin-bush connection of the leaf spring is lubricated with regular EP2 lithium grease, that grease burns, the lubrication is gone, and a possible leaf spring breakage can occur. We have developed our grease Eurol Grease CS-2/103-S for that."

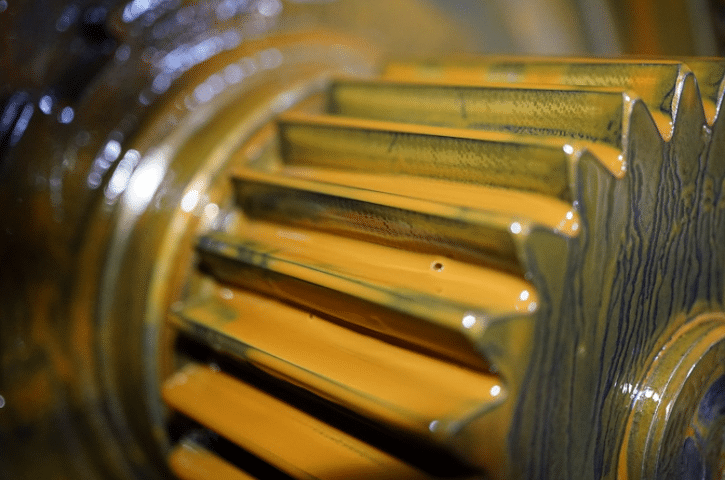

Another great example comes from 'Le Dakar.' "In Janus van Kasteren's rally truck from the Mammoet RallySport Team, we did not have to replace our grease (Eurol BIO Grease SI-000/101-S) in the wheel hubs once during the rally. Normally, extra hubs were taken along for replacement because everything burned each time. Now that was not the case. Ten days full throttle under extreme conditions and nothing had to be replaced, cool!" The teeth come out as new, wear is zero, and even the machining pattern of the teeth is still visible. "It's nice to see what you can achieve when you know where the cause of a problem lies. Then you can further develop and innovate your products."

New Developments Many innovations for road trucks find their way to the market from racing. "Our new products Eurol Additive-S Engine and Eurol Additive-S Flush for heavily loaded equipment are an example of product innovation." We have extensively tested the additives, both in practice during the Dakar Rally and the Morocco Desert Challenge, and on the test bench. What does it do in terms of emissions, and how much more power does it provide? "Racing is of course very nice and appealing. There you see innovations that provide more power but also fuel savings. Then you have an advantage to grab for a transport company, for example. Our new diesel additive (Eurol Additive-S Diesel) shows beautiful fuel savings. Then you should not think of ten percent, but if you consider that millions are spent by manufacturers to achieve that ..." Van der Veen is right; he really has the most fun job at Eurol!

Source: AMT (translated article)

Noroil gewinnt den Eurol Specialty Dealer of the Year Award 2024 dank starkem Wachstum im Bereich industrieller Schmierstoffe und technischer Flüssigkeiten in Norwegen.

Entdecken Sie die Eurol Swift Clean HD Wipes für mühelose Reinigung von Wasser und den Swift Clean 130 - jetzt auch erhältlich in ein 20L-Blik, ideal für häufigen Gebrauch....

Die Dakar-Rallye 2025 war ein großer Erfolg für die Eurol-Teams mit einem Doppelsieg auf dem zweiten Platz in der Gesamtwertung. Sowohl Toyota GAZOO Racing als auch Eurol R...

Nach fünf harten Dakar-Etappen genießen die Eurol-Teilnehmer einen wohlverdienten Ruhetag. Beide Teams erlebten Erfolge und Rückschläge.

Noroil gewinnt den Eurol Specialty Dealer of the Year Award 2024 dank starkem Wachstum im Bereich industrieller Schmierstoffe und technischer Flüssigkeiten in Norwegen.

Entdecken Sie die Eurol Swift Clean HD Wipes für mühelose Reinigung von Wasser und den Swift Clean 130 - jetzt auch erhältlich in ein 20L-Blik, ideal für häufigen Gebrauch....

Die Dakar-Rallye 2025 war ein großer Erfolg für die Eurol-Teams mit einem Doppelsieg auf dem zweiten Platz in der Gesamtwertung. Sowohl Toyota GAZOO Racing als auch Eurol R...

Nach fünf harten Dakar-Etappen genießen die Eurol-Teilnehmer einen wohlverdienten Ruhetag. Beide Teams erlebten Erfolge und Rückschläge.