Die entscheidende Rolle der Hochleistungsschmierun...

Extreme Bedingungen im Bergbau verursachen Verschleiß und Ausfallzeiten. Eurol bietet Lösungen zur Verbesserung der Lebensdauer und Effizienz von Maschinen.

17. Januar 2025

Automotive engines are required by law to become cleaner and the market demands more efficient engines. On the other side, the performance should increase. Car manufacturers accomplish this by downsizing gasoline engines and applying technologies like exhaust gas recirculation, catalytic converters, turbochargers and direct injection.

Because of these modifications, engine stress is ever increased. This in turn increases the chance of severe engine damage. The cause of engine damage is still heavily debated but one possible cause is LSPI.

LSPI is an unwanted and uncontrolled combustion, not to be confused with pinging. Modern vehicles operate in a gear as high as possible to maximise fuel efficiency. When accelerating in low RPM, the load on the engine is extremely high. At low RPM and under high loads in a TGDI (Turbocharged Gasoline Direct Injection) engine, LSPI can occur.

Low Speed Pre-Ignition is an unwanted phenomenon because the combustion takes place during the compression stroke; the moment that the crankshaft forces the piston upwards towards top dead centre. Fuel is injected into the combustion chamber during the compression stroke and carbon embers ignite the fuel. The gases expand while the piston is still compressing, resulting in an extreme increase in pressure in the combustion chamber.

When the combustion takes place during the compression stroke, this can cause serious damage to the engine, since the piston and all components below need to absorb the pressure shock. To keep the combustion chamber free from carbon particles, the engine oil needs to be able to remove deposits from the cylinder wall.

A critical factor in reducing LSPI events is choosing the correct engine oil. Every car manufacturer develops its own specific engines, which in turn all require their own engine oil. Roughly fifteen years ago, only three to four engine oils were required to service an entire fleet. Currently, over ten different types of oil are required.

To avoid breakdown and costly repairs, it is essential to use the correct engine oil. Eurol has a rich history in developing engine oil and has used this expertise to develop an oil with extra protection against LSPI. Eurol Ultrance ECO 0W-20 is one of these products. The cleaning properties of this motor oil prevent deposits in the engine and turbocharger.

Extreme Bedingungen im Bergbau verursachen Verschleiß und Ausfallzeiten. Eurol bietet Lösungen zur Verbesserung der Lebensdauer und Effizienz von Maschinen.

Eurol introduces the Ultrance Blue 0W-20, a fully synthetic fuel efficient engine oil. Eurol Ultrance Blue 0W-20 is specially developed for Ford EcoBlue diesel engines wher...

You probably are familiar with the following situation, you arrive at a traffic light and your engine stops running. Fortunately, it turns back on when you want to drive of...

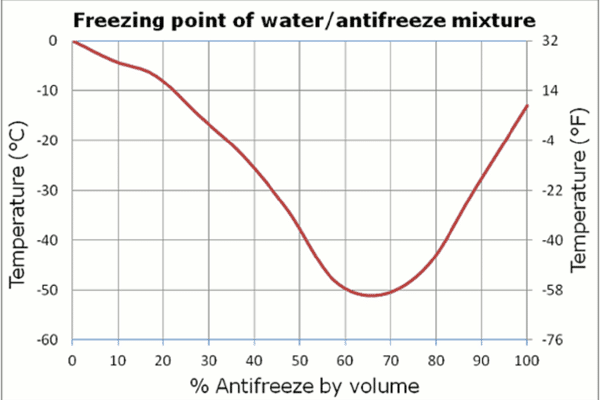

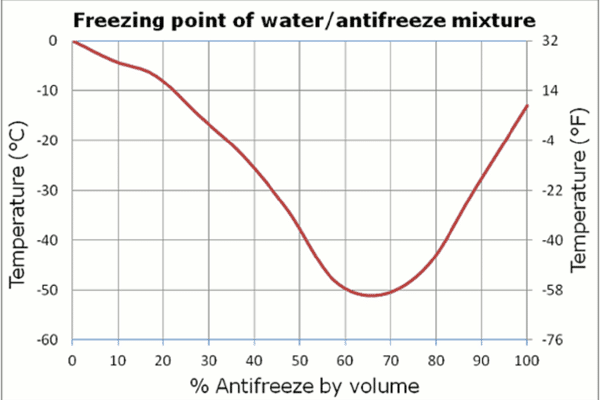

What does a coolant actually do, what are the differences between technologies, and what properties do they have? Why is it no longer possible to make a choice based on the...

Extreme Bedingungen im Bergbau verursachen Verschleiß und Ausfallzeiten. Eurol bietet Lösungen zur Verbesserung der Lebensdauer und Effizienz von Maschinen.

Eurol introduces the Ultrance Blue 0W-20, a fully synthetic fuel efficient engine oil. Eurol Ultrance Blue 0W-20 is specially developed for Ford EcoBlue diesel engines wher...

You probably are familiar with the following situation, you arrive at a traffic light and your engine stops running. Fortunately, it turns back on when you want to drive of...

What does a coolant actually do, what are the differences between technologies, and what properties do they have? Why is it no longer possible to make a choice based on the...