Die entscheidende Rolle der Hochleistungsschmierun...

Extreme Bedingungen im Bergbau verursachen Verschleiß und Ausfallzeiten. Eurol bietet Lösungen zur Verbesserung der Lebensdauer und Effizienz von Maschinen.

18. Dezember 2019

In general, the boiling point of a brake liquid is seen as an important indicator when establishing its quality. Brake fluids with too low a boiling point can cause reduced braking performance, especially during hard or prolonged braking. The more moisture is absorbed by a brake fluid, the lower its boiling point becomes. Brake fluids are hygroscopic, which means that they absorb moisture from the surrounding air.

One of the measuring systems on the market is the brake fluid test pen, which measures the electrical conductivity of a liquid. It then converts the conductivity measured and displays it as moisture content. This would be a good method in theory if all brake fluids had the same chemical composition and therefore the same conductivity. Unfortunately, the composition may vary from supplier to supplier, often making results unreliable.

In addition to measuring conductivity as a means of determining the boiling point of brake fluid, there are ones that can do so directly by heating it. Eurol has tested DOT 4 brake fluids from different suppliers with two comparable conductivity gauges and tested them for moisture content using an official laboratory method: the Karl Fischer method (ASTM D6304).

According to the Karl Fisher testing method, fresh brake fluids contain an average of 0.1% moisture. However, the conductivity meters gave different readings, even if the same samples were retested. Adding moisture to samples also resulted in incorrect readings and different readings from different testing devices. In some cases, the addition of moisture did not even show up at all in the readings, whereas significant amounts of moisture (up to 6%) had been added to the brake fluid being tested.

Finally, the brake fluid was tested using a boiling point device. The boiling point device we tested did not show any surprise readings during the tests, even when moisture was added to the brake fluid. This device indicated that all samples to which no moisture had been added met the DOT 4 specification of at least 230°C. Furthermore, the boiling point decreased as the moisture content was increased.

It would appear we cannot always rely on handy devices. The conductivity meters in particular, for instance the tester pen, hardly ever give a correct indication of the brake fluid’s condition. In theory, we would go as far as to say that blindly relying on the readings could be life-threatening if the brake fluid tester fails to detect an increase in moisture content. Looking at the test results, Eurol recommends using a boiling point device: the tests revealed that this method provides the most reliable results.

Extreme Bedingungen im Bergbau verursachen Verschleiß und Ausfallzeiten. Eurol bietet Lösungen zur Verbesserung der Lebensdauer und Effizienz von Maschinen.

You probably are familiar with the following situation, you arrive at a traffic light and your engine stops running. Fortunately, it turns back on when you want to drive of...

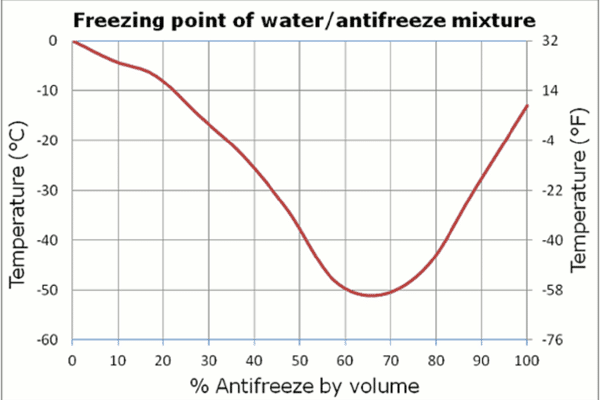

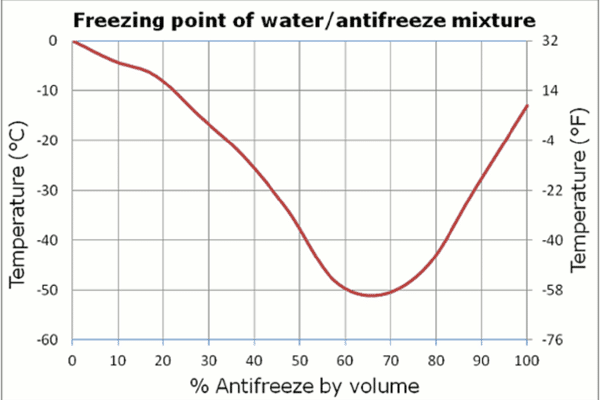

What does a coolant actually do, what are the differences between technologies, and what properties do they have? Why is it no longer possible to make a choice based on the...

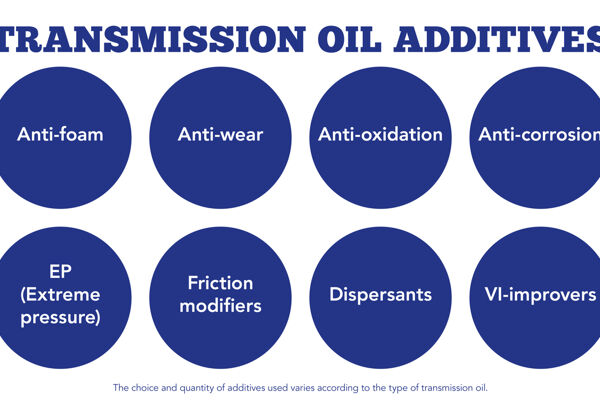

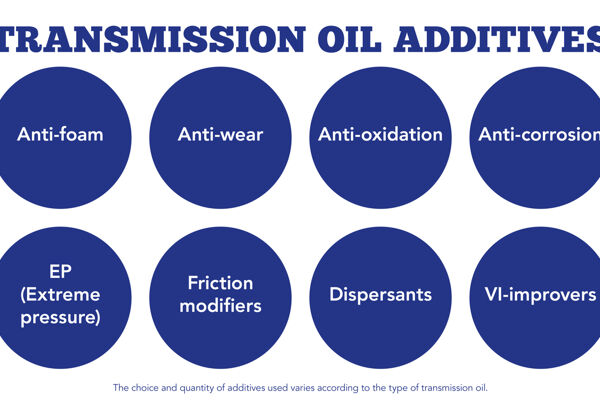

Fuel savings, smoother shifting, extended lifespan, and smaller sump capacities: these are the main driving forces for innovations in the field of transmission.

Extreme Bedingungen im Bergbau verursachen Verschleiß und Ausfallzeiten. Eurol bietet Lösungen zur Verbesserung der Lebensdauer und Effizienz von Maschinen.

You probably are familiar with the following situation, you arrive at a traffic light and your engine stops running. Fortunately, it turns back on when you want to drive of...

What does a coolant actually do, what are the differences between technologies, and what properties do they have? Why is it no longer possible to make a choice based on the...

Fuel savings, smoother shifting, extended lifespan, and smaller sump capacities: these are the main driving forces for innovations in the field of transmission.