Eurol motorcycle, car and truck teams ready for Da...

In Dakar 2026, Eurol will appear at the start with a wide representation. With four trucks, four cars and one motorcycle, it promises to be an exciting edition. ...

March 1, 2021

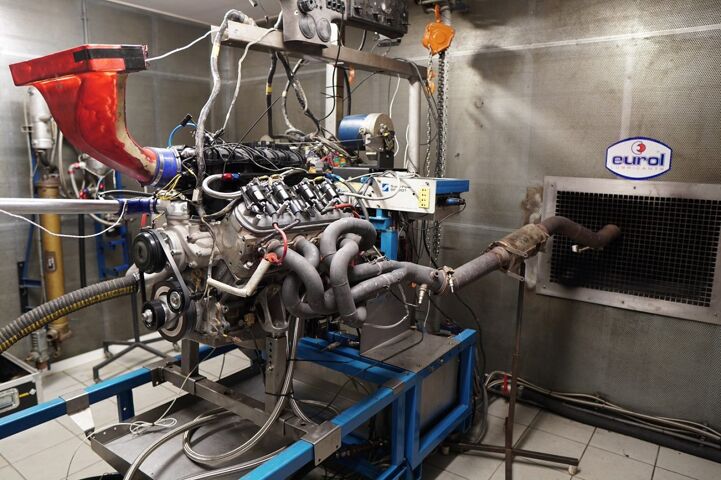

Increase in power: 1.5%

Reduction in wear: 66%

During the Dakar Rally, the engine runs at full load for hours, causing temperatures to rise. In these conditions, the engine oil often becomes contaminated with grains of sand as well as fuel. A regular 10W-60 cannot protect the engine against cylinder wear..

| Market | Race & Rally |

| Lubrication Point | Engine |

| Product | Eurol Specialty Racing 10W-60 |

| Article Number | S099002-1L |

Eurol Specialty Racing 10W-60 offers much better protection. This results in very low wear rates that are comparable to a healthy, standard engine. The viscosity also holds up very well and therefore ensures sufficient oil pressure at all times.

Tim Coronel, owner and driver: “The engine performed very well this year. With Eurol Specialty racing, the cylinder compression is still perfect. A recent dyno run showed the power output from the engine to be as before the Dakar, indicating less cylinder wear.”

In Dakar 2026, Eurol will appear at the start with a wide representation. With four trucks, four cars and one motorcycle, it promises to be an exciting edition. ...

Improved lubrication and corrosion protection increased reliability, lowered maintenance costs and reduced downtime in demanding tunnel drill applications.

Discover how modern two- and four-stroke engines evolve due to emission standards and what this means for maintenance, oil choice and machine performance.

Eurol introduces the Actence 0W-16, developed for the latest hybrid and petrol engines from Renault & Dacia.

In Dakar 2026, Eurol will appear at the start with a wide representation. With four trucks, four cars and one motorcycle, it promises to be an exciting edition. ...

Improved lubrication and corrosion protection increased reliability, lowered maintenance costs and reduced downtime in demanding tunnel drill applications.

Discover how modern two- and four-stroke engines evolve due to emission standards and what this means for maintenance, oil choice and machine performance.

Eurol introduces the Actence 0W-16, developed for the latest hybrid and petrol engines from Renault & Dacia.