Eurol obtains ISO 21469 certificate for incidental...

Eurol has obtained the ISO 21469:2006 certificate. With this certification, Eurol shows that it meets the internationally recognised standard for hygiene requirem...

January 23, 2024

In industrial companies where different fluids are used and stored, safety and correct identification are very important. Essential in this regard is the clear color coding of packaging when it comes to lubricants and oils. The use of specific color codes for lubricants not only helps prevent cross-contamination but also increases overall safety. In this article, we discuss lubricant color codes and how they contribute to maintaining a safe working environment.

The color codes are used to identify the type of lubricant in the packaging, this is important for the following reasons:

Prevention of cross-contamination: companies often use multiple types of lubricants. Using different color codes for different lubricants minimizes the risk of cross-contamination. For example: the use of red for a specific type of lubricant ensures that it is not accidentally used in a machine that requires a different lubricant.

Efficiency: Quick and easy identification of products through color coding improves operational efficiency. Maintenance personnel can quickly select the right lubricant for the job, reducing downtime and potential errors.

Our Eurol Specialty Lubricants also feature color coding:

Color coding can be used in conjunction with labeling. Labels can provide additional, more detailed information about the properties of the lubricant, recommended applications, and safety precautions.

Additionally, Eurol Specialty products suitable for incidental food contact (NSF H1, food grade) have a yellow highlighted text 'for incidental food contact' on the front label. These NSF H1 lubricants and cleaning agents may incidentally come into contact with food in and around food processing areas without endangering public health.

In summary, the lubricant color codes on Eurol Specialty products are an integral part of maintaining a safe and efficient industrial working environment.

Eurol has obtained the ISO 21469:2006 certificate. With this certification, Eurol shows that it meets the internationally recognised standard for hygiene requirem...

A practical case from a producer in the food industry, who has started saving up to €20,000 per year due to reduced maintenance and downtime thanks to Eurol Specialty produ...

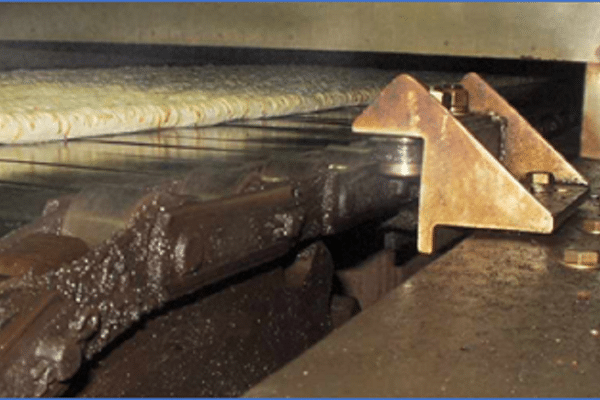

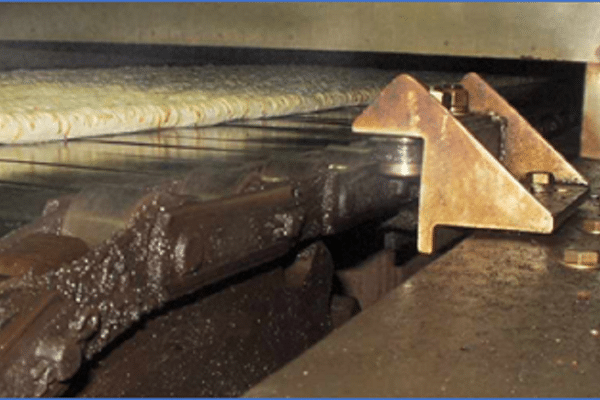

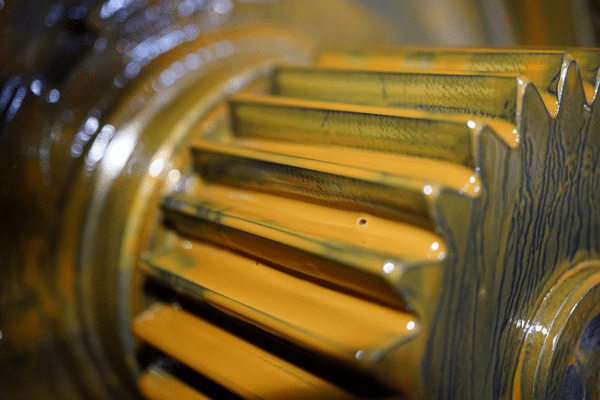

Chains and bearings in a tunnel oven need to be lubricated. However, this is often done with lubricants that are unsuitable for high-temperature applications.

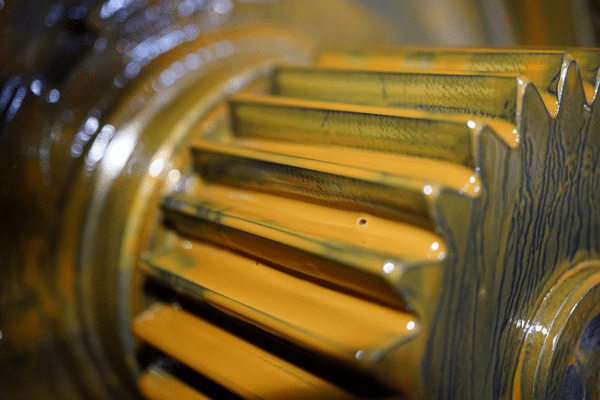

Grease is grease, right? "Not exactly, our lubricants are completely different in composition compared to regular lubricants." Automotive trade magazine AMT recently visite...

Eurol has obtained the ISO 21469:2006 certificate. With this certification, Eurol shows that it meets the internationally recognised standard for hygiene requirem...

A practical case from a producer in the food industry, who has started saving up to €20,000 per year due to reduced maintenance and downtime thanks to Eurol Specialty produ...

Chains and bearings in a tunnel oven need to be lubricated. However, this is often done with lubricants that are unsuitable for high-temperature applications.

Grease is grease, right? "Not exactly, our lubricants are completely different in composition compared to regular lubricants." Automotive trade magazine AMT recently visite...