The crucial role of high-performance lubrication i...

Extreme conditions in mining cause wear and downtime. Eurol offers solutions to improve the lifespan and efficiency of machinery.

4 de mayo

Como consecuencia de estos requisitos más estrictos, los fabricantes de camiones están desarrollando motores más eficientes y económicos. Estos avances tienen un impacto directo en las formulaciones de aceites para motores. Por ejemplo, las nuevas tecnologías de aceites para motores reducen la fricción en el motor, lo que se traduce en ahorro de combustible y reducción de CO2. Exploramos esto con más detalle en este artículo.

Los camiones deben cumplir con estrictos requisitos medioambientales, que incluyen emisiones limitadas de sustancias nocivas como monóxido de carbono (CO), hidrocarburos, NOx y partículas finas. Estos están regulados por las normas de emisiones Euro. Con el tiempo, estas normas se han vuelto considerablemente más estrictas. La norma actual es Euro VI. En comparación con su predecesora, Euro V, el límite máximo para la emisión de NOx (óxidos de nitrógeno) es un 80 por ciento menor. Además, la norma también requiere una garantía de que las emisiones se mantendrán bajas con el tiempo.

Está prevista la publicación de una nueva edición de las especificaciones ACEA en la primera mitad de 2021, y esperamos que los siguientes cambios se produzcan como resultado:

A diferencia de los automóviles, los camiones aún no están sujetos a límites de emisiones de CO2. Esto se debe a que la situación de los camiones es mucho más compleja debido a las muchas variaciones de tractor y remolque. Esta información se está mapeando actualmente para determinar los límites de emisiones de CO2. Existe una discusión abierta en la Unión Europea sobre una reducción del 3 por ciento para 2030 en comparación con hoy (2021), lo que sería un desafío monumental. Esta medida significaría que para entonces, los motores tendrían que usar un 30 por ciento menos de diésel en promedio. Parte de esa reducción se puede lograr mejorando la eficiencia del motor, pero se necesitarían otras medidas, como mejorar la aerodinámica, la elección de neumáticos, los combustibles alternativos y viajar en convoy.

Para cumplir con estas normas cada vez más estrictas, los fabricantes de camiones buscan continuamente formas de mejorar sus motores. Además de las modificaciones en los propios motores, los fabricantes también han introducido sistemas de post-tratamiento que capturan las sustancias nocivas liberadas y las convierten en sustancias menos dañinas. Los sistemas de post-tratamiento comunes incluyen el filtro de partículas, que minimiza la emisión de partículas al capturarlas, y el SCR o Reducción Catalítica Selectiva, que convierte el NOx en sustancias inocuas con la ayuda de AdBlue. También se utilizan convertidores catalíticos para acelerar la conversión de sustancias nocivas en sustancias inocuas.

Las tecnologías de aceites convencionales no ofrecen una protección continua a los sistemas de post-tratamiento, ya que tienden a contener demasiado azufre, fósforo y cenizas sulfatadas. Los sistemas de post-tratamiento requieren lo que se conoce como aceites 'bajo' y 'medio SAPS, que contienen cantidades menores de estas sustancias. 'SAPS' significa Sulphated Ash, Phosphorus y Sulphur. Esto requiere aditivos diferentes a los de los aceites convencionales. Las cenizas sulfatadas son el residuo que queda después de quemar aceite. Las cenizas sulfatadas obstruyen el filtro de hollín y no se pueden eliminar, a diferencia del hollín capturado. Algunos aditivos contienen fósforo, que puede acumularse en los convertidores catalíticos e impedir su función. El azufre, otro ingrediente en los aditivos, también se acumula en los convertidores catalíticos, así como en los sensores de NOx.

Las primeras especificaciones de aceites 'bajo SAPS' y 'medio SAPS' aparecieron en el mercado hace más de diez años. Hoy en día, los aceites para motores 'bajo SAPS' y 'medio SAPS' son comunes para la mayoría de los motores Euro VI y cumplen con las especificaciones de aceites que imponen límites de saps reducidos. Ejemplos incluyen ACEA E6 y E9, API CJ-4, CK-4 y FA-4, así como especificaciones de fabricantes como MB 228.51, Volvo VDS 4 y MAN M3677. Además, los camiones híbridos y eléctricos ocuparán una posición definitiva en el mundo de los camiones. En un futuro muy lejano, se espera que los motores de combustión actuales ya no se instalen en camiones nuevos: el objetivo a largo plazo es lograr emisiones 'cero' de los camiones.

El ahorro de combustible y, a su vez, las reducciones de CO2 se pueden lograr al reducir la fricción en el motor. La fricción en puntos de contacto metal con metal se puede prevenir con aceites base sintéticos especiales y aditivos (reductores de fricción).

‘El aceite SAE

Extreme conditions in mining cause wear and downtime. Eurol offers solutions to improve the lifespan and efficiency of machinery.

Seguramente te resulta familiar la siguiente situación: llegas a un semáforo y el motor se apaga. Afortunadamente, se vuelve a encender cuando quieres continuar. ¿Irritante...

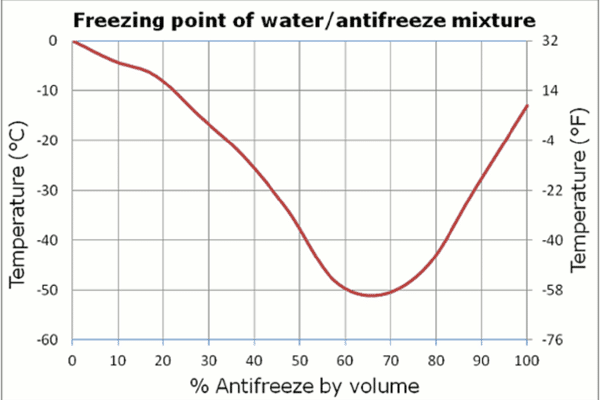

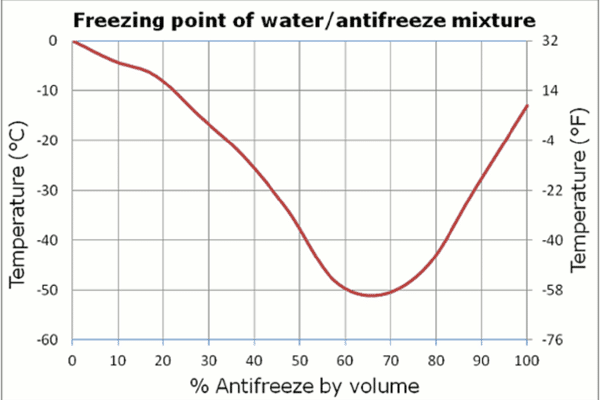

¿Qué función cumple realmente un refrigerante, cuáles son las diferencias entre tecnologías y qué propiedades tienen? ¿Y por qué ya no es posible elegir un refrigerante bas...

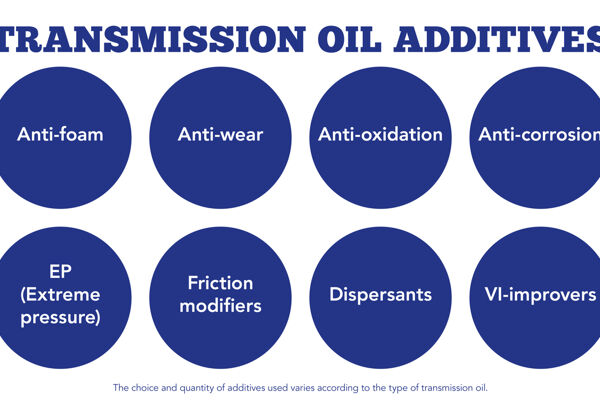

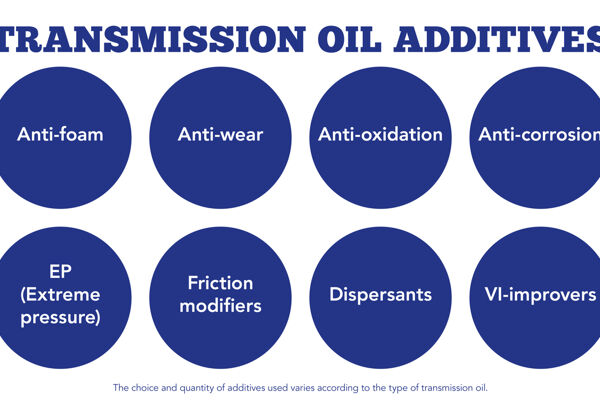

Ahorro de combustible, cambios de marcha más suaves, mayor vida útil y cárteres más pequeños: estos son los principales impulsores de la innovación en el ámbito de las tran...

Extreme conditions in mining cause wear and downtime. Eurol offers solutions to improve the lifespan and efficiency of machinery.

Seguramente te resulta familiar la siguiente situación: llegas a un semáforo y el motor se apaga. Afortunadamente, se vuelve a encender cuando quieres continuar. ¿Irritante...

¿Qué función cumple realmente un refrigerante, cuáles son las diferencias entre tecnologías y qué propiedades tienen? ¿Y por qué ya no es posible elegir un refrigerante bas...

Ahorro de combustible, cambios de marcha más suaves, mayor vida útil y cárteres más pequeños: estos son los principales impulsores de la innovación en el ámbito de las tran...