L'importance du TBN

Le TBN indique la capacité d'une huile à neutraliser les acides. Essentiel lors de l’utilisation de carburants riches en soufre et en conditions sévères, pour éviter corros...

9 mai 2023

Ces dernières années, les exigences en matière d’émissions pour les voitures sont devenues plus strictes. C’est en partie pour cette raison que les constructeurs automobiles optent de plus en plus pour des moteurs plus petits équipés d’un turbocompresseur. Un turbo permet d’envoyer plus d’air dans le moteur, ce qui permet de brûler davantage de carburant. Ensemble, l’air et le carburant supplémentaires offrent plus de puissance quand c’est nécessaire. La plupart du temps, cette puissance n’est pas utilisée, ce qui permet au moteur plus compact de suffire. Résultat : une consommation de carburant réduite, un moteur plus efficace et moins d’émissions de CO₂.

En fonctionnement, un turbo peut tourner à environ 150 000 tours/minute et atteindre des températures allant jusqu’à 350°C. Cela exerce une pression considérable sur tous les matériaux, y compris le lubrifiant. La moindre contamination peut alors avoir un impact important. Si le filtre à air laisse passer de la poussière ou d’autres impuretés, cela peut entraîner une usure du palier du turbo. De plus, les canaux d’huile peuvent se boucher sous l’effet des températures élevées, ce qui peut provoquer un blocage du turbo dans ses paliers. Un turbo endommagé réduit la puissance du moteur. À terme, des problèmes de turbo peuvent entraîner l’arrêt complet du moteur. Il est donc essentiel de les prévenir, et cela passe notamment par le bon choix de lubrifiant.

Un entretien régulier et conforme aux recommandations du constructeur est indispensable. Il est également essentiel de contrôler et remplacer les filtres à huile et à air selon le plan d’entretien.

L’huile moteur doit être changée correctement et à temps. En cas de trajets courts fréquents, des intervalles de vidange plus courts sont recommandés.

L’huile moteur utilisée doit répondre aux spécifications prescrites. La viscosité est également un critère important. Une huile trop fluide ne formera pas un film lubrifiant suffisant, surtout à haute température. À l’inverse, une huile trop visqueuse n’atteindra pas assez rapidement les zones critiques ou ne dissipera pas efficacement la chaleur. Une huile moteur de qualité réduit les risques de changements de viscosité et de contamination. Vous souhaitez savoir quelle huile est adaptée à votre véhicule ? Consultez alors notre Conseiller en huile.

Il est recommandé, après le démarrage, de laisser tourner le moteur à bas régime. Cela permet à l’huile de chauffer progressivement et de former un bon film lubrifiant dans le turbo.

Si, malgré tout, des problèmes de turbo apparaissent, il est important d’intervenir rapidement. Le remplacement d’un turbo peut facilement coûter plus de 1 000 €, mais il est parfois possible d’éviter un remplacement complet. En cas de problème, il est donc conseillé de consulter un spécialiste qui pourra poser un diagnostic et procéder à la réparation avec les pièces adéquates.

Le TBN indique la capacité d'une huile à neutraliser les acides. Essentiel lors de l’utilisation de carburants riches en soufre et en conditions sévères, pour éviter corros...

Les conditions extrêmes dans le secteur minier provoquent de l’usure et des arrêts machines. Eurol propose des solutions pour améliorer la durée de vie et l’efficacité des ...

Vous connaissez probablement la situation suivante : vous arrivez à un feu rouge et votre moteur s’arrête. Heureusement, il redémarre lorsque vous repartez. Irritant ou ing...

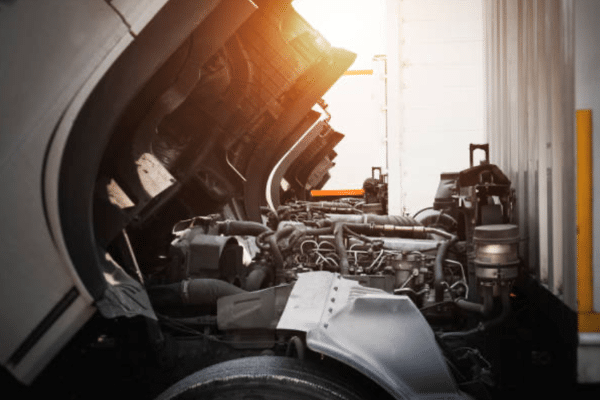

À quoi sert réellement un liquide de refroidissement, quelles sont les différences entre les technologies et quelles propriétés possèdent-elles ? Pourquoi n’est-il plus pos...

Le TBN indique la capacité d'une huile à neutraliser les acides. Essentiel lors de l’utilisation de carburants riches en soufre et en conditions sévères, pour éviter corros...

Les conditions extrêmes dans le secteur minier provoquent de l’usure et des arrêts machines. Eurol propose des solutions pour améliorer la durée de vie et l’efficacité des ...

Vous connaissez probablement la situation suivante : vous arrivez à un feu rouge et votre moteur s’arrête. Heureusement, il redémarre lorsque vous repartez. Irritant ou ing...

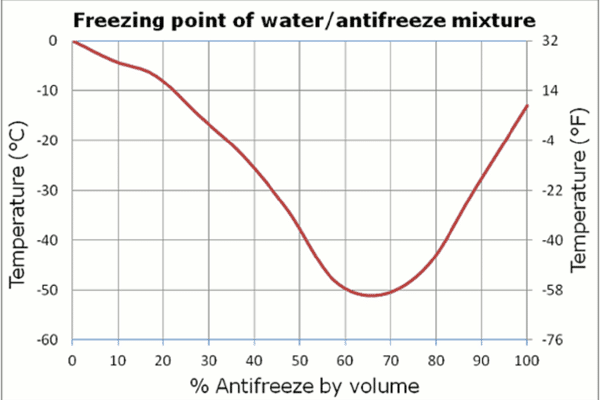

À quoi sert réellement un liquide de refroidissement, quelles sont les différences entre les technologies et quelles propriétés possèdent-elles ? Pourquoi n’est-il plus pos...