Eurol introduces Bag in box

Eurol launches the Bag in box with a capacity of 20 litres. This new packaging variant fits in the existing Eurol workshop rack of 12 x 20 litres.

4 janvier 2024

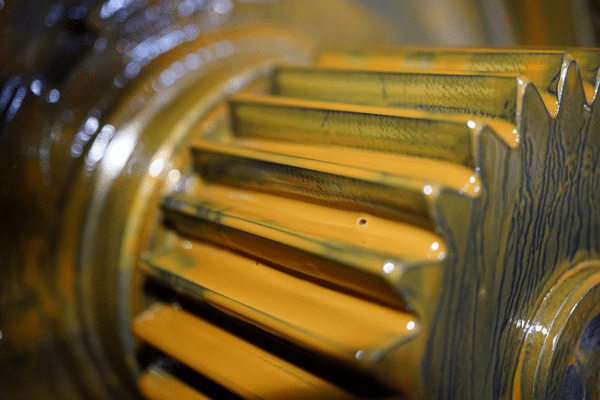

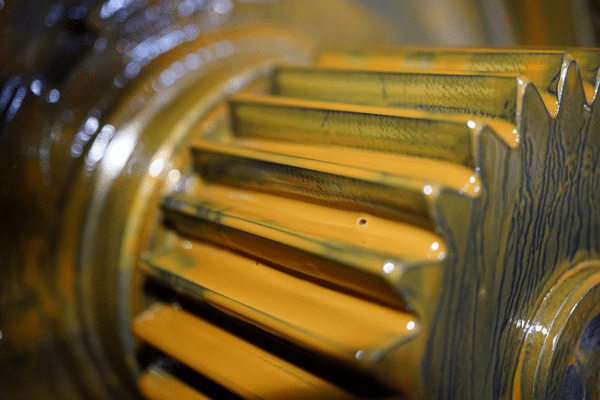

Ce lubrifiant récemment introduit contient la SYNGIS Technology de Eurol ainsi qu’un épaississant hybride, ce qui permet une réduction significative de la friction. Un test réalisé sur un concasseur de pierres démontre que cette technologie permet de réduire fortement la consommation d’énergie, et donc les émissions de CO2. En outre, EUROL E HD Grease HY-2/103-S offers high protection against wear, thereby preventing unexpected downtime. It also leads to lower maintenance costs.

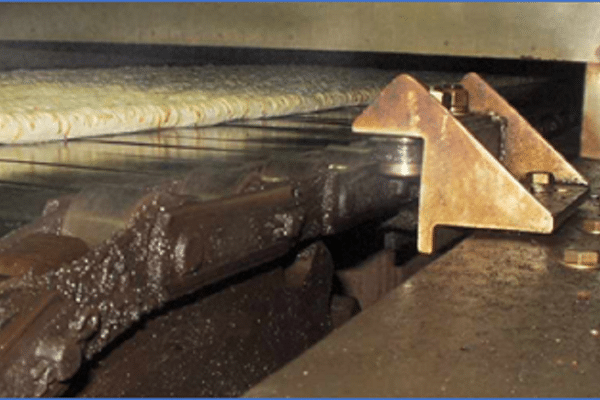

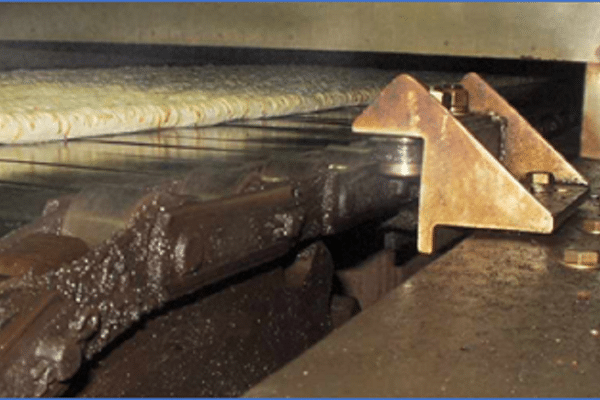

Pour réduire les pierres ou gravats en agrégats plus fins, on utilise des concasseurs dotés de roulements. Ces roulements fonctionnent dans des conditions extrêmes, soumis à des charges par à-coups, et nécessitent des lubrifiants de haute qualité pour garantir une performance optimale.

Pour évaluer l’impact du lubrifiant sur la consommation d’énergie, un test a été réalisé sur un concasseur de pierres dont les roulements ont d’abord été remplis d’une graisse Multi EP2 standard. La consommation d’énergie a été mesurée avec précision à l’aide d’une pince ampèremétrique sur le moteur électrique entraînant le concasseur. Ensuite, les roulements ont été remplis avec EUROL E HD Grease HY-2/103-S,et la consommation d’énergie a de nouveau été mesurée.

Les résultats sont remarquables. La consommation d’énergie du concasseur, équipé de roulements remplis avec EUROL E HD Grease HY-2/103-S, a considérablement diminué par rapport à la configuration avec la graisse Multi EP2 classique. Les mesures ont montré qu’une économie d’énergie allant jusqu’à 15 % pouvait être atteinte, selon le type de roulement, la vitesse, la charge, etc. Ces résultats ont des implications importantes, notamment dans les secteurs industriels utilisant intensivement des machines lourdes équipées de roulements. La réduction de la consommation d’énergie se traduit directement par une baisse des émissions de CO2, ce qui est un avantage pour les entreprises visant des certifications comme la CO2 Performance Ladder.

EUROL E HD Grease HY-2/103-S avec SYNGIS Technology de Eurol s’est révélée être une solution efficace pour économiser de l’énergie, notamment dans les roulements fortement sollicités. Le test sur un concasseur de pierres montre qu’une économie d’énergie pouvant aller jusqu’à 15 % est possible. Cela a un impact direct sur les émissions de CO2 de l’installation. C’est particulièrement important pour les entreprises engagées dans le développement durable et certifiées, par exemple, selon la CO2 Performance Ladder. Passer à des lubrifiants avancés comme EUROL E HD Grease HY-2/103-S est donc un investissement non seulement dans l’efficacité, mais aussi dans un avenir industriel plus durable avec une empreinte carbone réduite.

Il existe plusieurs façons de réduire la consommation énergétique d’équipements fortement sollicités grâce à la lubrification. Pour cela, Eurol a développé la gamme HD E-Line.

Eurol launches the Bag in box with a capacity of 20 litres. This new packaging variant fits in the existing Eurol workshop rack of 12 x 20 litres.

La graisse, c’est de la graisse, non ?« Pas exactement, nos lubrifiants sont totalement différents dans leur composition par rapport aux lubrifiants classiques. » Le ma...

Van den Boogaard est spécialisé dans le transport, le remorquage lourd et la location de grues. Les équipements, y compris les grues montées sur camion, doivent être dispon...

Les chaînes et roulements d’un four tunnel doivent être lubrifiés. Cependant, cela se fait souvent avec des lubrifiants inadaptés aux applications à haute température.

Eurol launches the Bag in box with a capacity of 20 litres. This new packaging variant fits in the existing Eurol workshop rack of 12 x 20 litres.

La graisse, c’est de la graisse, non ?« Pas exactement, nos lubrifiants sont totalement différents dans leur composition par rapport aux lubrifiants classiques. » Le ma...

Van den Boogaard est spécialisé dans le transport, le remorquage lourd et la location de grues. Les équipements, y compris les grues montées sur camion, doivent être dispon...

Les chaînes et roulements d’un four tunnel doivent être lubrifiés. Cependant, cela se fait souvent avec des lubrifiants inadaptés aux applications à haute température.