Eurol additive offers taxi company a smooth soluti...

A taxi company, with an extensive fleet of vehicles equipped with automatic transmissions, is experiencing increasing complaints about the shifting behavior of some of thei...

9 mai 2023

The article below will appear in Agri Trader's Test Yearbook 2023 in mid-January.

The most significant issues are visible at open lubrication points that regularly come into contact with manure, sand, and plant juices, such as pin-bush connections, bearings, and couplings. These lubrication points are the most susceptible to wear and require the most attention.

The temptation is great to opt for cheaper maintenance products, as these are the costs that are immediately visible. In these expensive times, these are the easiest savings. It is quite easy to use a grease cartridge of only a few euros on an agricultural machine worth several hundred thousand euros, without thinking carefully about the possible consequences. These are often lubricating greases based on old technologies, including lithium and graphite. In addition to the insufficient lubricating properties, these lubricants also often contain microplastics (including Teflon) and other chemical substances that do not pass the environmental test.

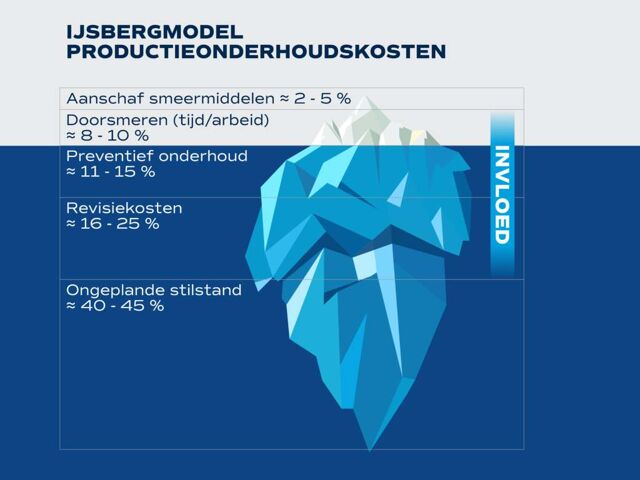

To give an idea of the costs of lubricants in relation to the total operational costs, the iceberg model provides visibility. It becomes clear that the costs for a lubricant only amount to 2 to 5% of the total, while the costs of repair, parts, and unplanned downtime can add up to 70% of the total costs. These latter costs are regularly underwater, and are therefore often invisible and difficult to measure.

In addition, the influence of lubricants on the costs that are 'underwater' is significant. In short, the right lubricant significantly reduces costs for preventive maintenance, overhaul costs, and unplanned downtime. The lubricant not only pays for itself, but even has a positive effect on the entire business operation.

Agricultural equipment puts lubricants to the test. Consider a combination of high-pressure load at low speed, exposure to aggressive (acidic) substances from, for example, manure components or plant juices. The result is extreme wear and corrosion.

So, what should a lubricant meet to prevent downtime and repairs? A lubricant should preferably ensure less wear and at the same time contribute to greater efficiency, fuel savings, and lower emissions. In addition, a good lubricant must be less harmful to people and the environment.

Eurol's development department has developed the SYNGIS technology to cope with these harsh conditions. The Eurol Specialty line of lubricants contains this technology consisting of modern additives that reinforce each other and ensure a synergistic effect. The result of this operation is that, even in the most extreme conditions, the lubrication of bearings and other components is maintained, and components are protected.

This prevents unwanted repairs and unplanned downtime more often. It is also important that the residual value of the lubricated equipment is higher because it remains in better condition than comparable machines with the same operating hours.

According to the manufacturer, the development of the Eurol Specialty lubricants is based on the best results with the lowest possible environmental impact. For example, many Specialty products are free of microplastics (PTFE) and contain fewer harmful substances for the user. In addition, better lubrication also saves fuel and reduces emissions. The SYNGIS Technology, therefore, meets modern requirements and is in line with future-proof business operations.

Met de Eurol Grease CS-2/501 werden alle drie toepassingen gesmeerd en beschermd tegen invloeden van de gewassappen. JvEsch kon van drie smeervetten, naar één smeervet voor het onderhouden van de maaimachines.

Er werd een afname van 20% tot 25% in de benodigde hoeveelheid smeervetten gerealiseerd. De totale jaarlijkse besparing door minder stilstand en reparaties bedraagt duizenden euro’s.

A taxi company, with an extensive fleet of vehicles equipped with automatic transmissions, is experiencing increasing complaints about the shifting behavior of some of thei...

Using Eurol Assembly Paste HT/FD for drilling equipment in the steel industry prevents carbonization, extends machine lifespan, and reduces downtime, saving over €50,000 an...

We introduce the Fultrax 75W-90 LS, a fully synthetic transmission oil with limited slip properties.

In the production of prefabricated decorative paving, a large automatic steel brush for keeping the molds clean plays a crucial role in ensuring quality.

A taxi company, with an extensive fleet of vehicles equipped with automatic transmissions, is experiencing increasing complaints about the shifting behavior of some of thei...

Using Eurol Assembly Paste HT/FD for drilling equipment in the steel industry prevents carbonization, extends machine lifespan, and reduces downtime, saving over €50,000 an...

We introduce the Fultrax 75W-90 LS, a fully synthetic transmission oil with limited slip properties.

In the production of prefabricated decorative paving, a large automatic steel brush for keeping the molds clean plays a crucial role in ensuring quality.