L’additif Eurol offre une solution fluide à une so...

Une société de taxis, disposant d’une vaste flotte de véhicules équipés de boîtes automatiques, fait face à des plaintes de plus en plus nombreuses concernant le comporteme...

11 juillet 2023

Less downtime and longer lubrication intervals

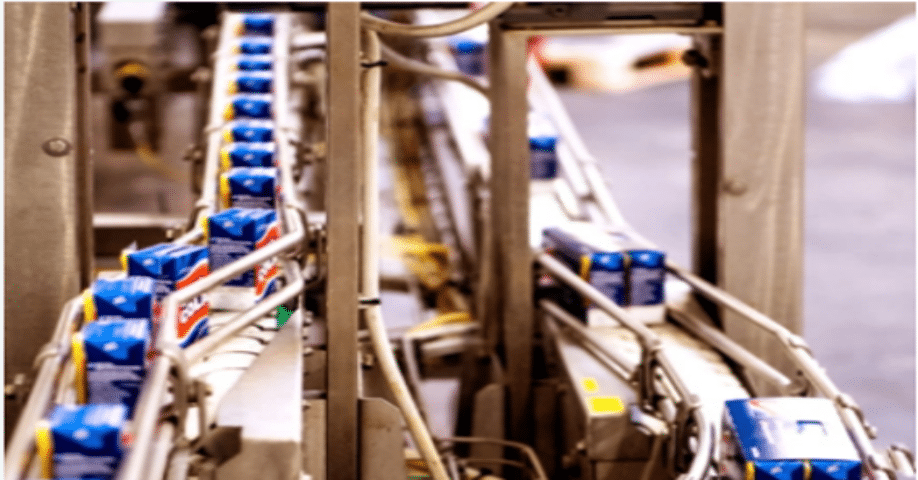

A Danish producer in the food industry was using an H1-certified lubricant that did not meet the required product specifications. Additionally, the lubricant was not resistant to common factors such as sugar, cleaning agents, and moisture. This led to additional maintenance costs and production losses, negatively impacting the business process.

| Market | Food Industry | |

|---|---|---|

| Product | Eurol Specialty Chain Lube S-AC 38 FD | |

| Lubrication Point | Conveyor belt | |

| Article Number | S001101AER | |

| Product Usage | More efficient lubricant |

The H1 Food certification means that lubricants can only consist of a limited number of components. However, this can compromise both the service life and lubricating properties of the lubricant. The Eurol Chain Lube S-AC 38 FD contains SYNGIS Technology, which allows for no compromises in terms of service life or lubricating properties, despite being an H1-certified product. This results in minimal maintenance costs and production losses.

Une société de taxis, disposant d’une vaste flotte de véhicules équipés de boîtes automatiques, fait face à des plaintes de plus en plus nombreuses concernant le comporteme...

L’utilisation de la pâte de montage Eurol Assembly Paste HT/FD pour les équipements de forage dans l’industrie sidérurgique empêche la carbonisation, prolonge la durée de v...

Dans la production de pavés décoratifs en béton préfabriqué, une grande brosse en acier automatique servant à maintenir les moules propres joue un rôle crucial dans le main...

Le nettoyage des éléments coulissants avec du nettoyant pour freins était un processus laborieux et peu favorable du point de vue de la santé au travail. L’opérateur devait...

Une société de taxis, disposant d’une vaste flotte de véhicules équipés de boîtes automatiques, fait face à des plaintes de plus en plus nombreuses concernant le comporteme...

L’utilisation de la pâte de montage Eurol Assembly Paste HT/FD pour les équipements de forage dans l’industrie sidérurgique empêche la carbonisation, prolonge la durée de v...

Dans la production de pavés décoratifs en béton préfabriqué, une grande brosse en acier automatique servant à maintenir les moules propres joue un rôle crucial dans le main...

Le nettoyage des éléments coulissants avec du nettoyant pour freins était un processus laborieux et peu favorable du point de vue de la santé au travail. L’opérateur devait...