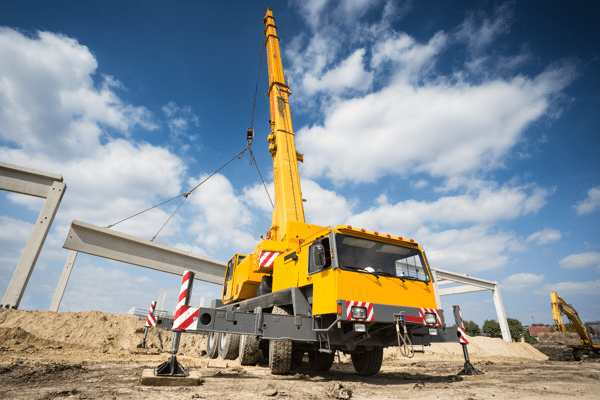

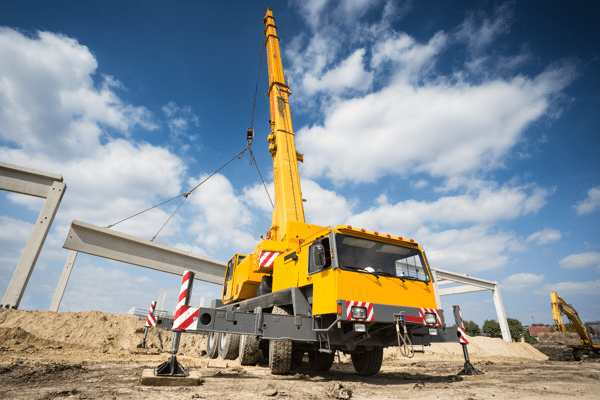

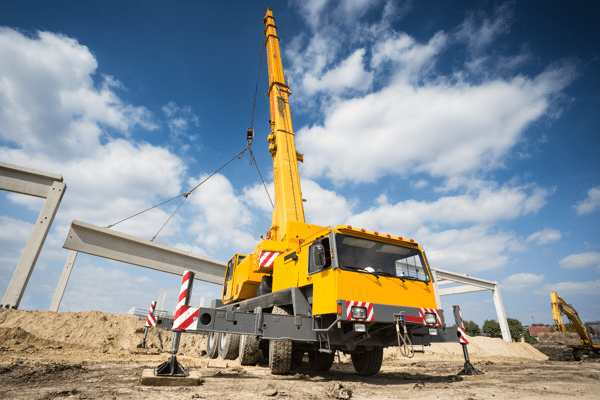

Vertical transport with maximum efficiency

In the vertical transport sector, proper lubrication of sliding parts and steel cables is crucial. Outdated greases can lead to malfunctions and increased maintenance. Mode...

9 mai 2023

A fifth wheel normally lasts as long as the life of a truck, but in Bolk Transport's situation an extra fifth wheel is most of the time needed. This is because the fifth wheel is very heavily loaded in extreme conditions. The application of the wrong grease causes an enormous resistance between the fifth wheel plate and trailer, resulting in grooves, iron filings and a broken fifth wheel as a consequence.

| Market | Truck & Transport |

| Lubrication Point | Fifth wheel |

| Product | Eurol Specialty Grease CS-2/502-S |

| Article Number | S005121-110G |

| Product Usage | Lubricating Greases |

Eurol Specialty Grease CS-2/502-S reduces wear and ensures that the fifth wheel keeps running smoothly. The grease stays on the fifth wheel plate and does not leak. This makes the grease last longer, is more durable in use and therefore less harmful to the environment.

Gert-Jan Grobbink, Head of Equipment, Bolk Transport: "We have around 150 trucks on the road with a fifth wheel. Using Eurol Specialty grease provides us with ample savings on fifth wheel discs, because we don't have to install a new fifth wheel halfway through the lifetime of a truck."

In the vertical transport sector, proper lubrication of sliding parts and steel cables is crucial. Outdated greases can lead to malfunctions and increased maintenance. Mode...

Reducing the CO2 footprint of industrial processes is becoming increasingly important. In this, energy saving plays a crucial role.

Le nettoyage des éléments coulissants avec du nettoyant pour freins était un processus laborieux et peu favorable du point de vue de la santé au travail. L’opérateur devait...

La lubrification des éléments coulissants est souvent effectuée avec de la graisse standard. Contrairement à l’huile, cette graisse ne s’applique pas facilement au pinceau....

In the vertical transport sector, proper lubrication of sliding parts and steel cables is crucial. Outdated greases can lead to malfunctions and increased maintenance. Mode...

Reducing the CO2 footprint of industrial processes is becoming increasingly important. In this, energy saving plays a crucial role.

Le nettoyage des éléments coulissants avec du nettoyant pour freins était un processus laborieux et peu favorable du point de vue de la santé au travail. L’opérateur devait...

La lubrification des éléments coulissants est souvent effectuée avec de la graisse standard. Contrairement à l’huile, cette graisse ne s’applique pas facilement au pinceau....