The crucial role of high-performance lubrication i...

Extreme conditions in mining cause wear and downtime. Eurol offers solutions to improve the lifespan and efficiency of machinery.

27 de junho

Fluid Management is a fairly new term within the garage world. Previously, there were few types of fluids to keep a garage running. Times have changed and car manufacturers demand different fluids for different makes and types. To this end, Eurol continuously develops specific fluids that ensure optimal performance, lower fuel consumption and lower emission levels.

This development has a direct impact on the garage owner who has to stock all these different fluids, in different quantities. There is still much to be gained in this regard. For instance, there is often a lack of physical space, knowledge and the right tools. As a result, the risk of mistakes, i.e. using the wrong fluid, increases and the efficiency of the work actually decreases. This situation can be avoided by managing all necessary fluids in a garage. This involves not only controlling the use of the fluids but also purchasing, storing and disposing of them.

How broadly and professionally garages address these issues depends, among other things, on the size and type of business. All-round garages deal with a multitude of products because of the large number of different cars they service. Roughly speaking, there are two sides to managing these fluids: physical storage of the various products on the one hand, and the associated administration on the other.

To store and manage the large number of different liquids in an orderly manner, there are several systems. Eurol has a handy 20-litre can with a corresponding compact metal display. With this system, up to 12 different liquids can be stored in one square metre. The sturdy can has a bleed valve so that draining is hassle-free. Moreover, accessories such as a sturdy pouring jug and robust taps are available. Should spillage nevertheless occur, the large drip tray catches the liquid. For correct coding, Eurol has magnetic strips available. For 60-litre drums, Eurol has a similar metal display with storage of 6 in a square metre.

Administration is often a problem. Which fluids come in, how much of which is used, for which customer and when is it necessary to reorder which fluid? For these questions, a fluid management system offers a solution. This is special software linked to sensors that measure the level of the various bulk tanks in which the liquids are stored.

Eurol offers such a solution that remotely monitors the level in your bulk tank. In practice, it proves difficult to keep good track of how much liquid each bulk tank still contains. In the worst case scenario, employees 'suddenly' find out that a tank is empty, preventing certain customers from being served until stocks are replenished. Because sensors monitor the level, they can give an early indication of when to buy in. You get a signal when the lower limit is reached. New stock is delivered by mutual agreement so that you never run out of liquids.

Er bestaan ook afgiftemeters die u ondersteunen bij het aftappen van een specifieke hoeveelheid uit de tank. De gewenste hoeveelheid is uiteraard in te stellen en voorkomt dat er onnodig veel vloeistof wordt getapt. De software levert u gegevens om bij te houden wie, wanneer, welke hoeveelheden en voor welk doel heeft gebruikt. Daarbij heeft de gebruiker de mogelijkheid om de software volledig af te stemmen naar eigen eisen en wensen.

Moreover, the data can also increase your workshop efficiency. Understanding the volumes of liquids is useful when it comes to determining which pack sizes to buy in. This in turn has a positive impact on the purchasing price. In addition, a good comparison can be made between the quantity of liquid ultimately passed on to a customer - based on the quantity actually consumed - and the quantity ordered. Larger differences in this may indicate leakage, theft or inefficient use.

Finally, the system can be a godsend for buying precisely additional products that serve customers even better. For example, Eurol oil and fuel additives. These additives can bring significant benefits both technically and commercially. For example, additives prevent and remedy certain technical problems that are increasingly common due to bio-components in fuels and more sophisticated engine technologies. When properly explained, customers are willing to pay more for this. Eurol has additives in one-shot packs so that no residues occur.

For anyone who determines that fluid management in the workshop needs to improve, it would be wise to increase their knowledge. Eurol helps you do this with advice and support. Furthermore, we offer workshop materials that contribute to the optimal management and control of your fluids.

Extreme conditions in mining cause wear and downtime. Eurol offers solutions to improve the lifespan and efficiency of machinery.

You probably are familiar with the following situation, you arrive at a traffic light and your engine stops running. Fortunately, it turns back on when you want to drive of...

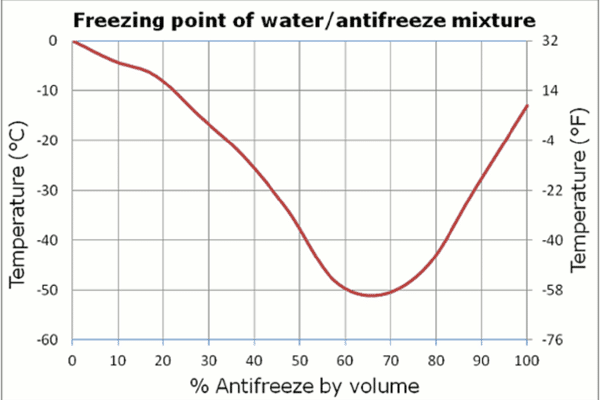

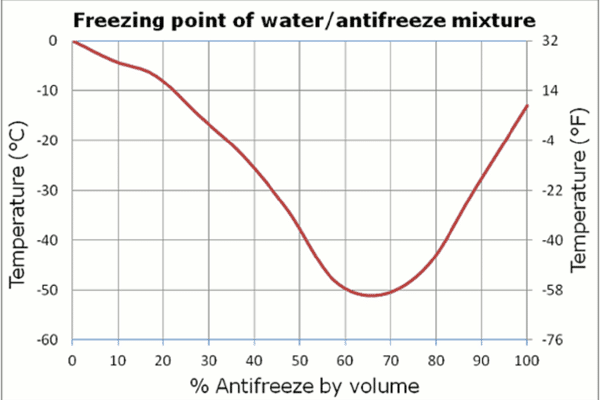

What does a coolant actually do, what are the differences between technologies, and what properties do they have? Why is it no longer possible to make a choice based on the...

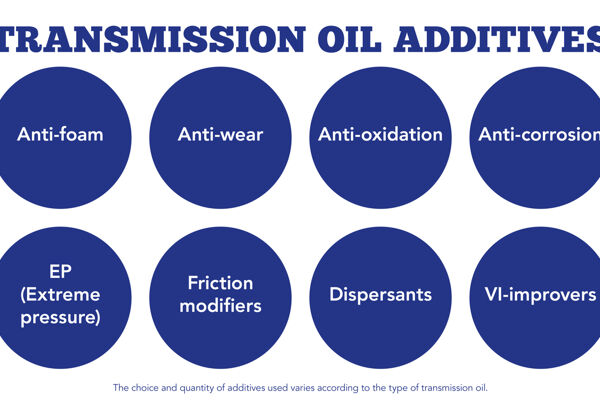

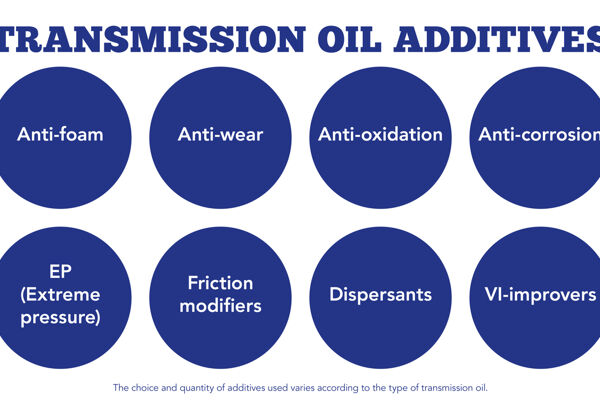

Fuel savings, smoother shifting, extended lifespan, and smaller sump capacities: these are the main driving forces for innovations in the field of transmission.

Extreme conditions in mining cause wear and downtime. Eurol offers solutions to improve the lifespan and efficiency of machinery.

You probably are familiar with the following situation, you arrive at a traffic light and your engine stops running. Fortunately, it turns back on when you want to drive of...

What does a coolant actually do, what are the differences between technologies, and what properties do they have? Why is it no longer possible to make a choice based on the...

Fuel savings, smoother shifting, extended lifespan, and smaller sump capacities: these are the main driving forces for innovations in the field of transmission.