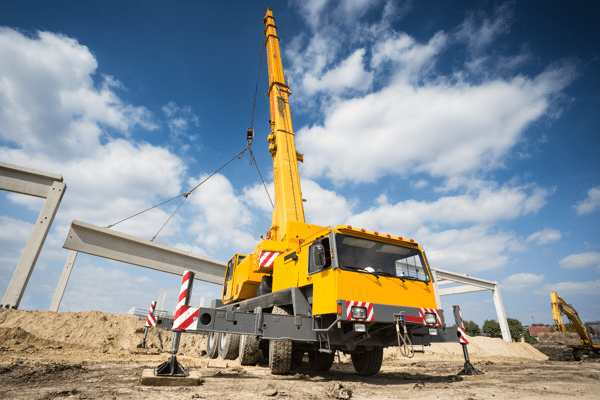

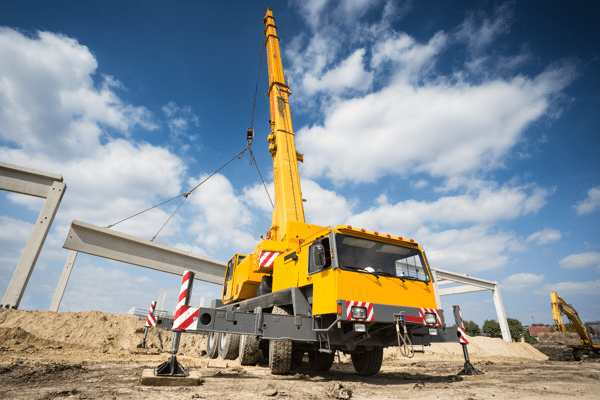

Lubrication drilling equipment steel industry

Using Eurol Assembly Paste HT/FD for drilling equipment in the steel industry prevents carbonization, extends machine lifespan, and reduces downtime, saving over €50,000 an...

14 de março

However, there is some hesitation, and rightly so, as the reputation of the first-generation biodegradable lubricants from the '80s and '90s was not good. Developments have progressed since then. Nowadays, there are machines running smoothly on the latest generation of biodegradable hydraulic oil, some having surpassed 20,000 operational hours without issues.

Today, we can confidently say that the performance and lifespan of a hydraulic system are not negatively affected by switching to a modern biodegradable oil, such as Eurol E Heavy Duty Lube 46 BIO. There is no higher risk of downtime or damage. The SYNGIS Technology significantly reduces friction in the system, saving energy. This is an even greater advantage with electric equipment as it extends battery life.

However, there are some rules to consider when transitioning from mineral hydraulic oil to biodegradable hydraulic oil. While theoretically, the two types of oils can mix well, the presence of old mineral hydraulic oil in the system can negatively affect the lubricating properties and lifespan of the new oil. Adding new oil does not extend the oil's service life.

We provide two sets of instructions for transitioning from regular mineral hydraulic oil to biodegradable hydraulic oil. One set is without dismantling machine parts, and the other is with dismantling machine parts.

Oil change without dismantling machine parts: Drain the hydraulic system, leaving about 10% to 20% (depending on brand, machine type, etc.) of the old hydraulic oil in the pump, lines, filters, cylinders, and the tank. Replace the filters and then fill the hydraulic system to the prescribed level with the new biodegradable hydraulic oil. Run the machine for at least 5 minutes to ensure any remaining old hydraulic oil is homogeneously mixed with the new biodegradable hydraulic oil. Then, change the oil a second time.

Oil change with dismantling machine parts: When dismantling the machine, the amount of old oil remaining in the pump, cylinders, lines, filters, and tank can be limited to about 5% - 10%. This means that a maximum of two oil changes should suffice. Also, run the machine for at least 5 minutes after each change.

Using Eurol Assembly Paste HT/FD for drilling equipment in the steel industry prevents carbonization, extends machine lifespan, and reduces downtime, saving over €50,000 an...

We introduce the Fultrax 75W-90 LS, a fully synthetic transmission oil with limited slip properties.

In the production of prefabricated decorative paving, a large automatic steel brush for keeping the molds clean plays a crucial role in ensuring quality.

In the vertical transport sector, proper lubrication of sliding parts and steel cables is crucial. Outdated greases can lead to malfunctions and increased maintenance. Mode...

Using Eurol Assembly Paste HT/FD for drilling equipment in the steel industry prevents carbonization, extends machine lifespan, and reduces downtime, saving over €50,000 an...

We introduce the Fultrax 75W-90 LS, a fully synthetic transmission oil with limited slip properties.

In the production of prefabricated decorative paving, a large automatic steel brush for keeping the molds clean plays a crucial role in ensuring quality.

In the vertical transport sector, proper lubrication of sliding parts and steel cables is crucial. Outdated greases can lead to malfunctions and increased maintenance. Mode...