Eurol additive offers taxi company a smooth soluti...

A taxi company, with an extensive fleet of vehicles equipped with automatic transmissions, is experiencing increasing complaints about the shifting behavior of some of thei...

27 de julho

For light-duty vehicles, there will be less stringent changes compared to heavy-duty vehicles, although the heavy-duty sector has more time for implementation. Type approvals issued for cars and light commercial vehicles from July 2025 must comply with the Euro 7 emission standards, but for heavy-duty commercial vehicles, this only applies from July 2027. However, some manufacturers are requesting a postponement to meet the requirements.

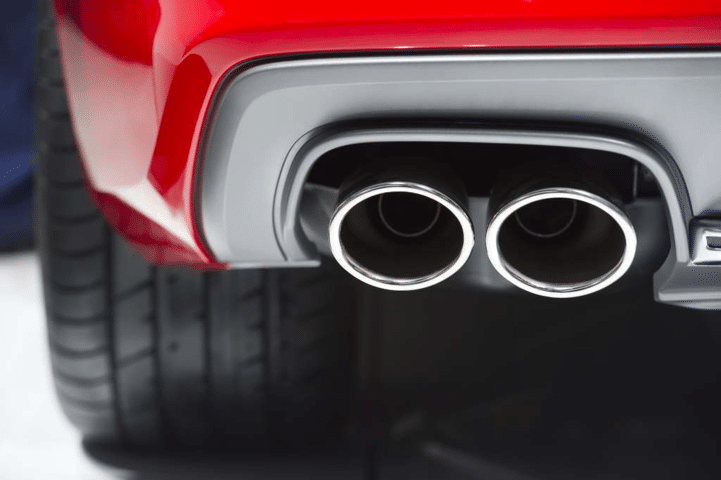

The emphasis of the Euro 7 standard is on reducing the impact of vehicles on air quality. Not only exhaust emissions are regulated, but attention is also paid to the fine particles emitted by brakes and tires while driving.

“Light-duty” is specified as “vehicles with up to 8 seats or up to 3.5 tons of load capacity”, which includes passenger cars and light commercial vehicles such as vans and pickups. The Euro 7 standard for light-duty is more of an evolution of the current Euro 6 standard. It involves less drastic changes than initially thought because the EU’s intention is to implement a zero-emission policy for this segment by 2035. It has been concluded that too strict limits for the Euro 7 standard would be too costly for the relatively short investment period.

One major change is that the Euro 7 standard will no longer make a technological distinction between “conventional” gasoline engines, gasoline direct injection (GDI) engines, and diesel engines. Under the Euro 7 standard, all these engines will have the same limits. For instance, under the Euro 6 standard, diesel engines were allowed to emit more NOx, while the particle limits for GDI engines were stricter compared to other gasoline engines.

The Euro 6 norm set limits for particles larger than 23 nanometers (Particulate Number, or PN23) – meaning particulate matter. With the Euro 7 norm, limits are set for particles larger than 10 nanometers (PN10). This means that not only smaller pollutants need to be taken into account, but also that more different types of pollutants are being considered.

As it may be known, an engine is most polluting during the first few minutes. The engine is still cold, combustion is inefficient, and the exhaust aftertreatment systems do not work as effectively. Therefore, the Euro 7 standard includes, in addition to the normal driving cycle (RDE -> Real-world Driving Emissions), a test specifically for short trips of less than 10 kilometers. Please refer to the graph below for a comprehensive overview of the limits.

| NOx | PM | PN10 | CO | THC | NMHC | NH3 | |

| RDE (mg/km) | 60 | 4,5 | 4×1011 | 500 | 100 | 68 | 20 |

| Trips <10km (mg/trip) | 600 | 45 | 6×1012 | 5000 | 1000 | 680 | 200 |

Declaration about the substances: Carbon Monoxide (CO) is toxic, THC and NMHC cause smoke formation and irritate the respiratory tract. Ammonia is included for the first time in the Euro 7 standard. Ammonia is also irritating to the respiratory tract and is a byproduct of the catalytic conversion process in gasoline exhaust emissions.

The period in which emission requirements must be met has doubled with the Euro 7 standard. While Euro 6 regulations required vehicles to meet emission limits for 100,000 kilometers or 5 years, Euro 7 (light-duty) vehicles must meet these limits for 200,000 km or 10 years.

An even greater impact than the doubling of the lifetime of the emission standards is the monitoring of compliance. Euro 7 vehicles must monitor themselves, meaning they have to register their own emissions and whether the vehicle still meets the set limits. For this purpose, the existing OBD (On Board Diagnose) system must evolve into an OBM (On Board Monitoring) system. This means many additional sensors and a computer where the data can be stored and read. If a trend of deviations is discovered for certain types of vehicles, it is not unthinkable that manufacturers of those vehicles may be required to take appropriate measures, such as fines or the recall and/or modification of their products/vehicles to ensure compliance with the standards for the full 200,000 km or 10 years.

The expectation for gasoline vehicles is that GDI will remain the most used technology. However, we will see a wider application of gasoline particulate filters, even with conventional gasoline engines. The pores of the particulate filters will become smaller to filter the smaller particles, potentially leading to faster clogging. With diesel engines, the focus is on NOx emissions, especially during cold starts. We will see more “close coupled” systems in the exhaust gas aftertreatment process, where the catalysts are placed closer to the engine to heat up the system faster and make it work properly earlier.

The disadvantage of this is that the exhaust gases may still be so hot because they have just come out of the turbo that the pollution from the lubricant (phosphorus and sulfur chemistry) poisons the catalyst coating, as this high temperature can accelerate this effect. An alternative to “close coupling” is electric (pre)heating of the exhaust gas aftertreatment system. Because the regeneration process of Diesel Particulate Filters (DPF) is also included in the cycle, we will also see changes in filter design and regeneration strategy there.

To meet the set limits and continue to meet them during the specified lifespan, the use of the correct lubricants and fuels is very important. There are several challenges ahead for lubricants and fuels in Euro 7 vehicles. Research shows that lubricants with relatively high or medium SAPS values (sulfur and phosphorus chemistry used for wear protection) generate particles during combustion, especially in the critical PN10 to PN23 range. These particles cause the fine pores of the filters in the exhaust system to clog slowly, which in turn causes higher backpressure. Higher backpressure leads to more resistance and thus higher fuel consumption, i.e., higher emissions.

In addition to attention to particulate matter, there is also attention to reducing friction to keep the internal resistance in the engine as low as possible. When motor oil is used for hybrid vehicles, more attention is needed for corrosion protection in the lubricant. The engines are expected to run less frequently, and the lubricant is not heated through and through, which promotes condensation – the mixing of moisture.

The use of high-quality fuels plays a crucial role in meeting and continuing to meet emission standards. Pollution in the combustion chamber or on the injector can affect injection patterns, leading to incomplete combustion and increased pollution. Research shows that injector fouling affects emissions. When less fuel is injected at a time, the engine computer will increase the injection time. Extending injection times by 20% will result in four times as many particles being emitted.

Pollution caused by incorrect lubricants and low-quality fuels can prevent compliance with required standards, which will be detected by sensors. Any deviations must be identified and corrected. Failure to do so can result in legal consequences, and the vehicle will not pass the periodic inspection. Pollution can also lead to potentially high costs because sensitive sensors may become damaged and require replacement. It is increasingly important to choose the right consumables and maintenance products. Eurol closely monitors developments and develops products that are compatible with Euro 7 vehicles. This also applies to any applications of top-up additives to clean the engine through the oil and/or fuel system or to promote optimal combustion.

For more information or advice, please contact our Technical Service department or your local Eurol consultant. Also, keep an eye on the Eurol online oil advisor for specific vehicle recommendations.

A taxi company, with an extensive fleet of vehicles equipped with automatic transmissions, is experiencing increasing complaints about the shifting behavior of some of thei...

It's summer vacation! Are you going on holiday by car? Then we have five handy tips for the fluids to prevent problems with your car.

Visit Eurol during Automechanika in Frankfurt from September 10 to 14, 2024. Hall 12, stand E11.

Lubricant color codes are an integral part of maintaining a safe and efficient industrial working environment. Read more in this knowledge article.

A taxi company, with an extensive fleet of vehicles equipped with automatic transmissions, is experiencing increasing complaints about the shifting behavior of some of thei...

It's summer vacation! Are you going on holiday by car? Then we have five handy tips for the fluids to prevent problems with your car.

Visit Eurol during Automechanika in Frankfurt from September 10 to 14, 2024. Hall 12, stand E11.

Lubricant color codes are an integral part of maintaining a safe and efficient industrial working environment. Read more in this knowledge article.